ARD2M CE Approved Smart Motor Protectors for Protecting Motors and Power Monitoring

Series of products: Products

Series of products: Power Monitoring and Controlling Devices

Series of products: Smart Motor Protectors

- Product Description

- Parameters

- Q&A

- Download

-

Overview

The ARD2M motor protector (hereinafter referred to as the protector) is suitable for low-voltage motor circuits with rated voltage up to 380V and integrates protection, measurement, control, communication, operation and maintenance.

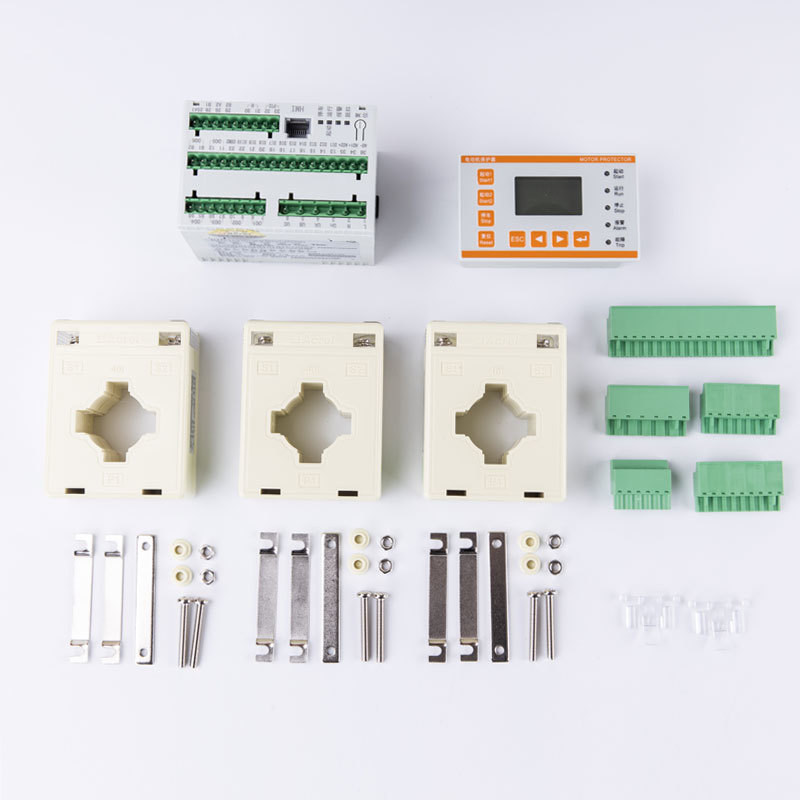

Its perfect protection function ensures the safe operation of the motor, with logic programmable function, can meet a variety of control methods. The product adopts split structure, which is composed of main body, panel, mutual inductor and optional communication module, and can adapt to the installation of various cabinets.

The Product Implementation standards: ——GB/T14048.4-2020 Low-voltage switchgear and control gear -- Part 4-1: Contactors and motor starters -- Electromechanical contactors and motor starters (including motor protectors); ——JB/T 10736-2007 Low voltage motor protector.

Coding Rule

Dispaly

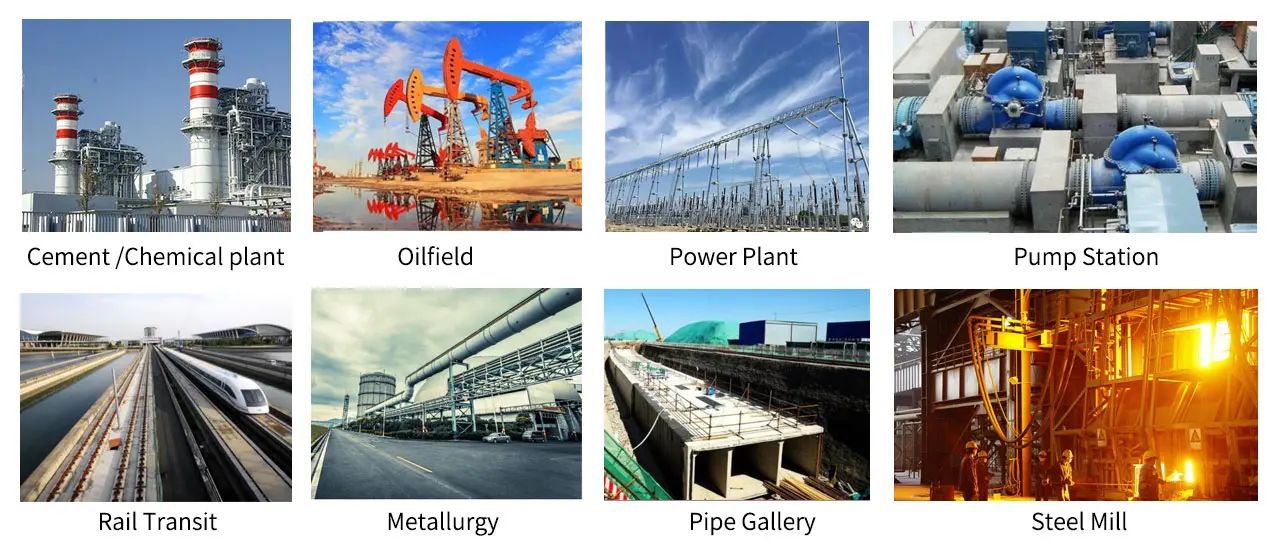

Application

Function

Type

Function

Functional configuration

Standard function

Optional function

Protection function

Fixed time overload

√

Inverse time overload

√

Starting timeout

√

Phase loss

√

Voltage unbalance

√

Current unbalance

√

Locked-Rotor

√

underload

√

External fault

√

Block

√

Temperature protection(PTC/NTC)

√

Residual current(One only)

grounding

√

leakage

√(leakage)

Phase sequence

√

Under voltage

√

Over voltage

√

Under power

√

Over power

√

Te time protection

√

Overflow protection

√

Alarm of starting times

√

Running time alarm

√

Fault frequency alarm

√

Control mode

Protection mode

√

Direct start mode

√

Two-step mode

Two-speed mode

Voltage loss restart

√

Communication function

1 channel Modbus-RTU communication

√

2 channels Modbus-RTU communication

√

1 channel Profibus-DP communication

√

Switching input

8 channel DI

√

Relay output

5 channel DO

√

Analog output

1 channel DC4-20mA

√

Event record

Start record, stop record, DI displacement record, restart record, (support communication transmission)

√

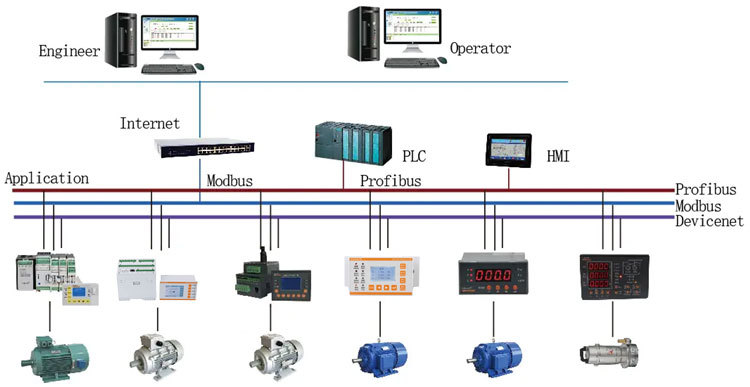

Network

Product Features

■ Support power parameter measurement (U, I, P, Q, S, PF, F, EP, EQ), voltage and current imbalance degree, voltage and current positive sequence, negative sequence, zero sequence component, three-phase voltage phase Angle, residual current.

■ Protection functions include overload inverse time, overload definite time, grounding, starting timeout, leakage, underload, locked-rotor, obstruction, short circuit, phase, overflow, imbalance (current, voltage, power, less power, over voltage, under voltage, phase sequence, temperature, external fault, tE time, running time alarm, fault alarm.

■ 8 channels programmable DI input, the default use of DC24V power supply, or external active wet contact can be selected (see the selection table).

■ 5 programmable DO output, to meet the direct starting, star - triangle starting, auto-transformer starting, and other starting modes, can be through the communication bus to achieve the master station to the motor remote control "start/stop".

■ Optional anti-shaking function: support immediate restart of shaking power and restart of voltage loss.

■ MODBUS_RTU and PROFIBUS DPV1 communication modules are available for selection.2 MODBUS_RTU communication channels or MODBUS_RTU+PROFIBUS DPV1 communication modules can be chosen.

■ Optional 1 channels DC4-20MA analog output interface, connected with DCS system, can realize the monitoring of field equipment.

■ With fault record, start record, stop record, DI displacement record, restart record and other records of various events, you can view a number of motor operation and maintenance information.

■ The display interface supports Chinese/English LIQUID crystal display

Dimension

Wiring

Package

Product Description:

Product Description:- PView

- high-performance

- requirements

-

Main parameters

The standard switch quantity of ARD2M is 8DI and 5DO, and the switch quantity type is shown in Table 1:

Table 1

Main switch classification

Code

DI is the dry contact, and the external power supply of DO is AC220V

K1

DI is the wet contact, the input is DC110V, and the external power supply of DO is AC220V

K2

DI is the wet contact, the input is DC220V, and the external power supply of DO is AC220V

K3

DI is the wet contact, AC220V input, and DO external power supply is AC220V

K4

The corresponding relation between ARD2M current specification and the rated current and power of the applicable motor is shown in Table 2:

Table 2

Protector current specification (A)

Ratio setting

Primary side coil number of transformer

Applicable scope of motor (kW)

Suitable for motor Rated current range (A)

1

Support

1circle

0.12-999

0.1-5000

5

1cirlce

0.12-999

0.5-5000

25

Does not

support

1cirlce

3-11

6.3-25

100

1circle

15-45

25-100

250

1circle

55-132

63-250

800

1circle

160-250

250-800

Additional function of ARD2M are shown in Table 3:

Table 3

Additional function

code

Additional function

code

Energy metering

Ep

SOE Event record

SR

4-20mA analog output

M

Temperature protection

T

1channel

communication

Modbus-RTU

C

2channel

communication

Modbus-RTU

2C

Profibus-DP

CP

Modbus-RTU+

Profibus-DP

CCP

Anti - electric shock function

SU

Leakage protection

L

Remarks:

(1)The motor with rated current of 0.4-1.6A can choose the 1A specification motor protector,and the transformer is wound 1 times.The motor with rated current of 1.6-6.3A can choose the 5A specification motor protector,and the transformer is wound 1 time.

(2)Integrated current transformer is used for integrated protector with current specification of 100A and below;The split current transformer is used for the current specification of 100A and below;

250A and 800A current specifications use another type of split current transformer. For the external dimensions of the transformer, please refer to the "external dimensions and installation".

(3)The temperature measurement support sensor type is PTC or NTC or PT100.

(4)After the leakage function (L) is selected, each protector is equipped with a leakage transformer. The dimensions of the leakage transformer are shown in the section "overall dimensions and installation". Leakage transformer is equipped with 2m ± 10cm secondary line as standard. If you need other length, please contact the manufacturer.

ARD2M technical indicators are shown in Table 4:

Table 4

Technical parameters

Technical indicators

Protector auxiliary power supply

AC85-265V/DC100-350V

Rated working voltage of the motor

AC220V / 380V,50Hz / 60Hz

Rated operation current of the motor

1 (0.1A-1.6A)

Integrated/Split current transformer

5 (1.6A-6.3A)

25(6.3A-25A)

100(25A-100A)

250(63A-250A)

Split current transformer

800(250A-800A)

Relay output contact capacity

Impedance load

AC250V、10A

Switching input

8 channels of passive dry contact (active DC110V, DC220V, AC220V input can be optional)

Communication

RS485 Modbus_RTU,Profibus DP

Environment

Working temperature

-10ºC~55ºC

Storage temperature

-25ºC~70ºC

Relative temperature

≤95﹪No condensation, no corrosive gas

Altitude

≤2000m

Pollution levels

3 level

Protection grade

IP65(installed on the cabinet panel)

Installation category

III级

Functional configuration

ARD2M Functional configuration shown in Table 5:

Table 5

Type

Function

Functional configuration

Standard function

Optional function

Protection function

Fixed time overload

√

Inverse time overload

√

Starting timeout

√

Phase loss

√

Voltage unbalance

√

Current unbalance

√

Locked-Rotor

√

underload

√

External fault

√

Block

√

Temperature protection(PTC/NTC)

√

Residual current(One only)

grounding

√

leakage

√(leakage)

Phase sequence

√

Under voltage

√

Over voltage

√

Under power

√

Over power

√

Te time protection

√

Overflow protection

√

Alarm of starting times

√

Running time alarm

√

Fault frequency alarm

√

Control mode

Protection mode

√

Direct start mode

√

Two-step mode

Two-speed mode

Voltage loss restart

√

Communication function

1 channel Modbus-RTU communication

√

2 channels Modbus-RTU communication

√

1 channel Profibus-DP communication

√

Switching input

8 channel DI

√

Relay output

5 channel DO

√

Analog output

1 channel DC4-20mA

√

Event record

Start record, stop record, DI displacement record, restart record, (support communication transmission)

√

-

Related Products

Product inquiry

We will contact you within one working day. Please pay attention to your email.

![[object Object] [object Object]](https://omo-oss-image.thefastimg.com/portal-saas/new2023080419495759710/cms/image/138ba837-b50d-4ff3-a73c-2e6a2379c522.jpg)