Acrel AHE100 Wireless Temperature and Humidity Sensor for Switchgear Cable/Busbar Temperature and Humidity Monitoring

Series of products: Products

Series of products: Wireless Temperature and Humidity Monitoring

Series of products: Power Monitoring and Controlling Devices

- Product Description

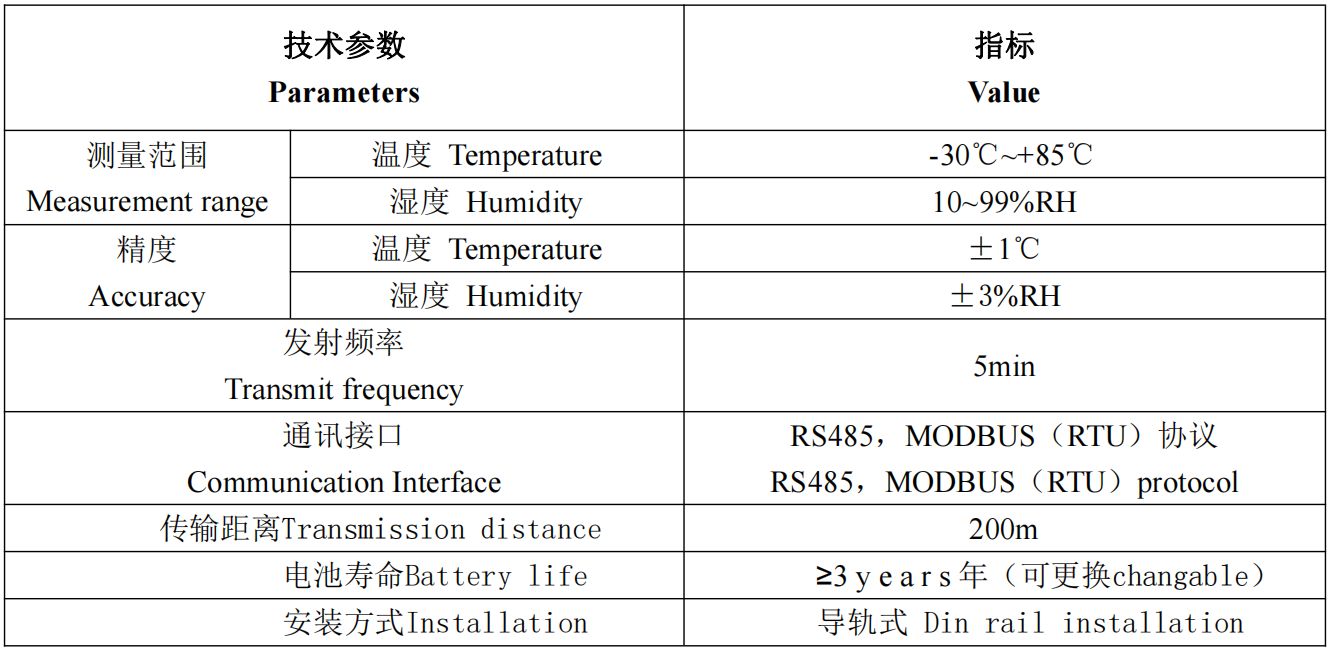

- Parameters

- Q&A

- Download

-

Overview

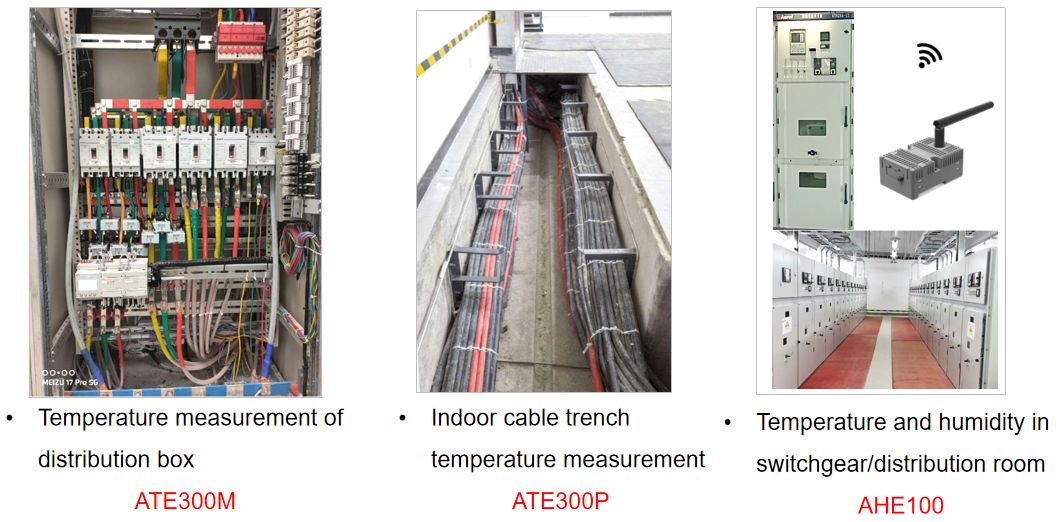

AHE wireless temperature and humidity sensor is mainly used for the detection of internal temperature and humidity in medium and high voltage switch cabinets, terminal boxes, ring network cabinets, box transformers and other equipment. The module adopts a special shell, which has good ventilation effect and exquisite appearance, which can effectively protect the internal components, increase the service life, and is convenient for installation and wiring.

Dispaly

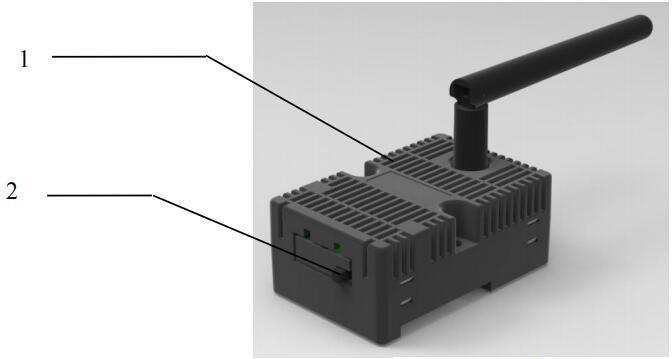

AHE 无线温湿度传感器,采用导轨(DIN35mm)安装方式,使用前需打开电池开关。The AHE wireless temperature and humidity sensor adopts the guide rail (DIN35mm) installationmethod, and the battery switch needs to be turned on before use.1 —— 无线温湿度传感器主体 Wireless temperature and humidity sensor main body2 —— 电池开关 Battery switch

AHE 无线温湿度传感器,采用导轨(DIN35mm)安装方式,使用前需打开电池开关。The AHE wireless temperature and humidity sensor adopts the guide rail (DIN35mm) installationmethod, and the battery switch needs to be turned on before use.1 —— 无线温湿度传感器主体 Wireless temperature and humidity sensor main body2 —— 电池开关 Battery switchFunction

● Temperature measurement range: -30℃~+85℃

● Humidity measurement range: 10~99%RH

● Temperature measuring accuracy: ±1℃

● Humidity measuring accuracy: ±3%RH

● Transmit frequency: 5 min

● Communication Interface: RS485, Modbus-RTU protocol

● Tansmission distance: 200 m

● Battery life: ≥3 years (changable)

● Auxiliary power supply: DC24V

● Installation: Din rail installation

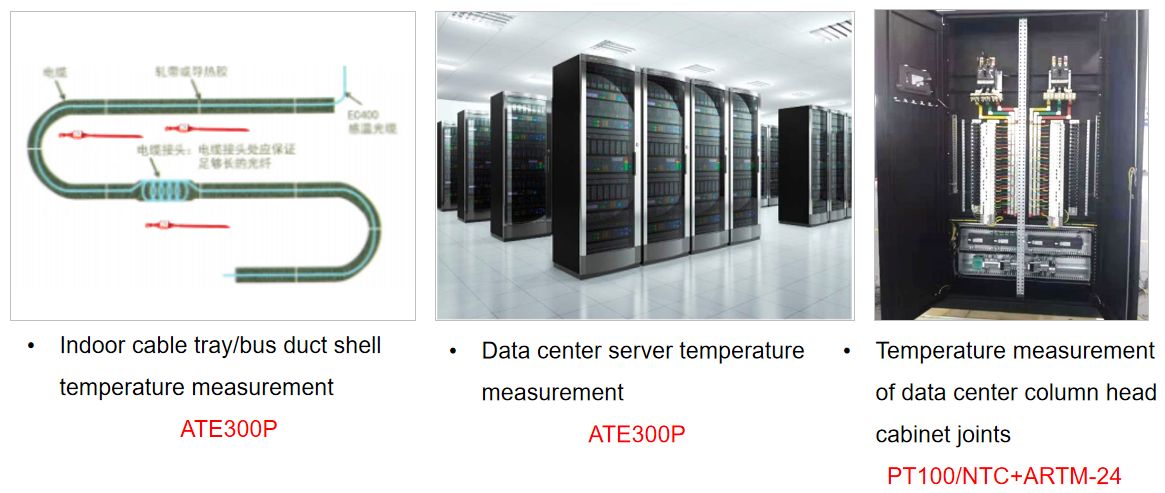

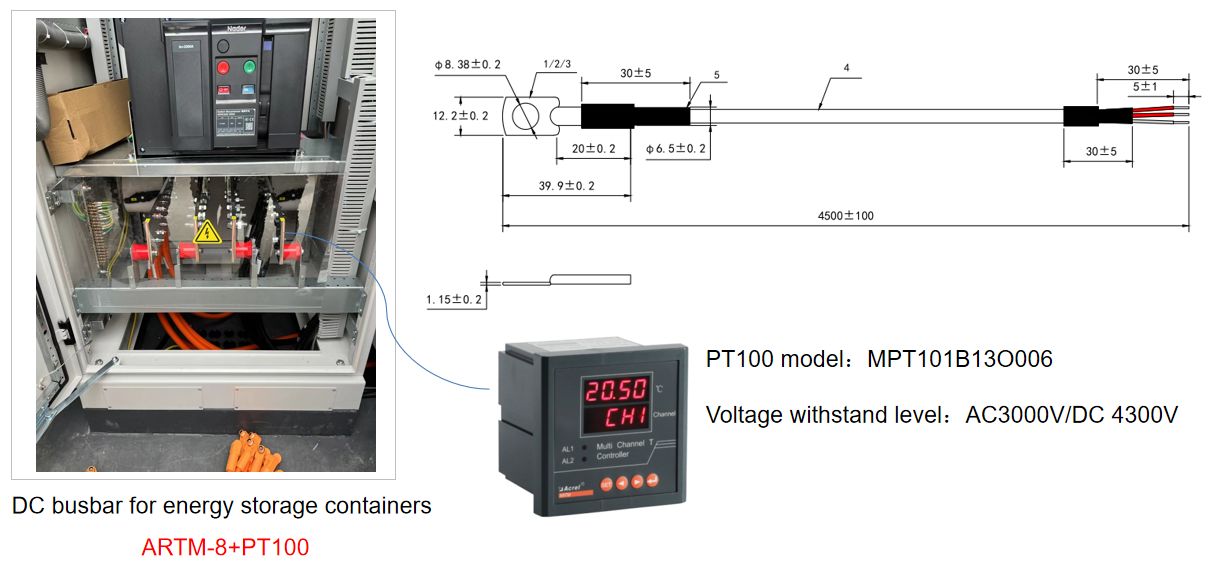

Application

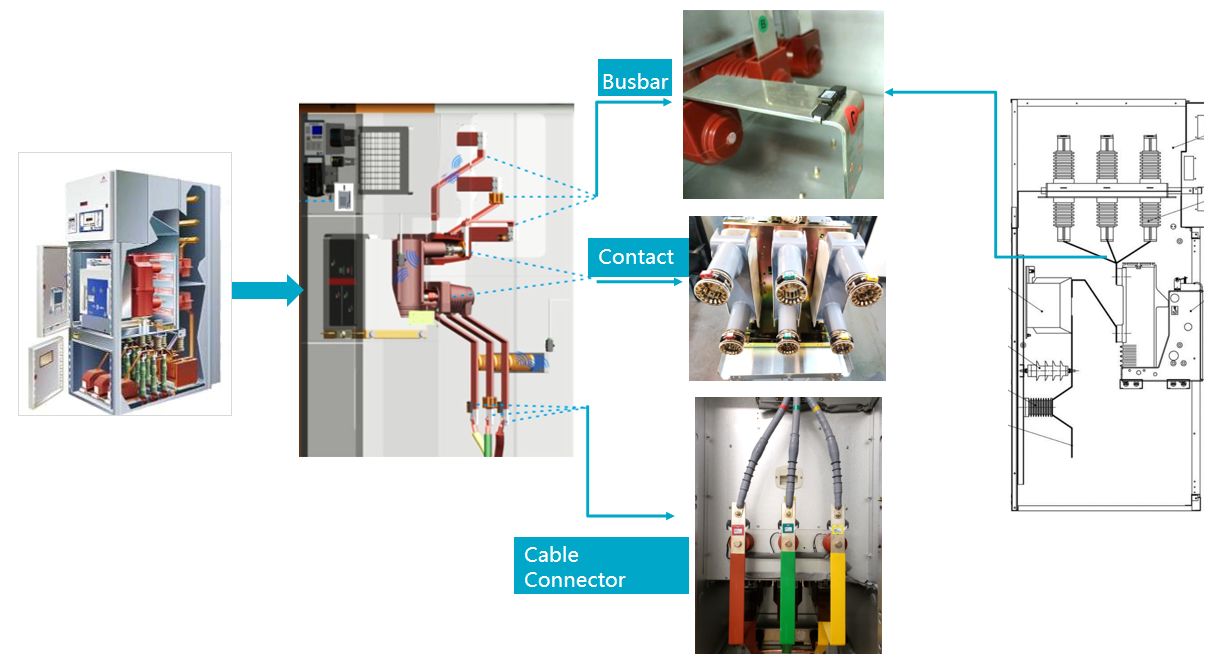

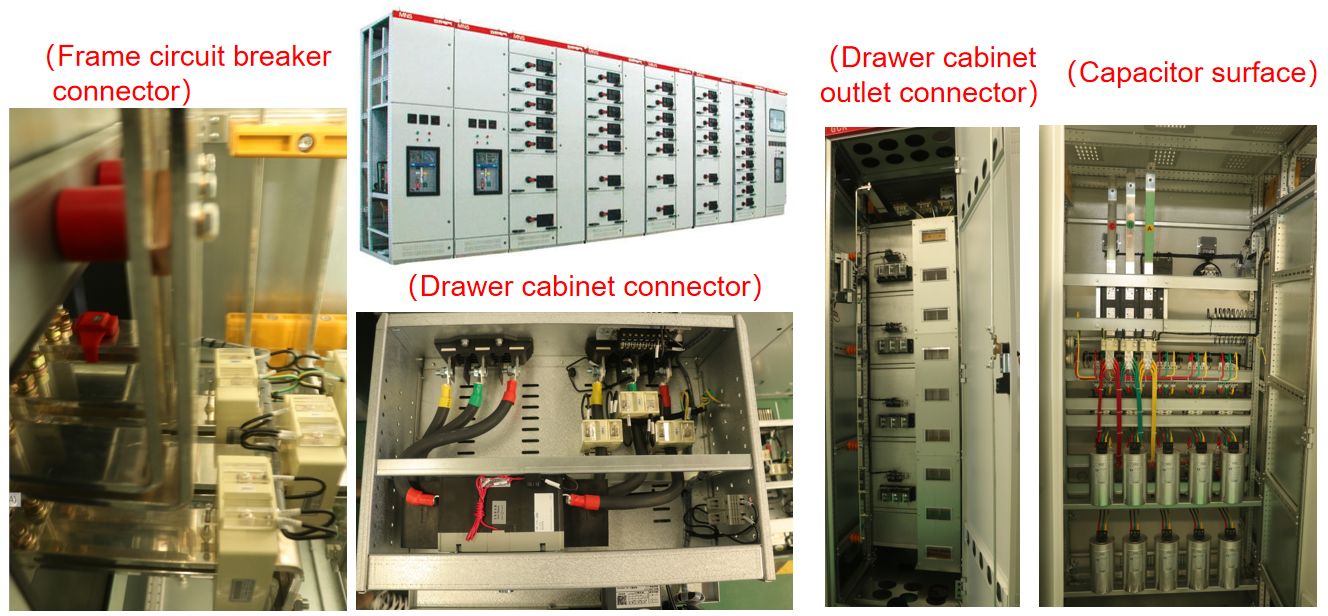

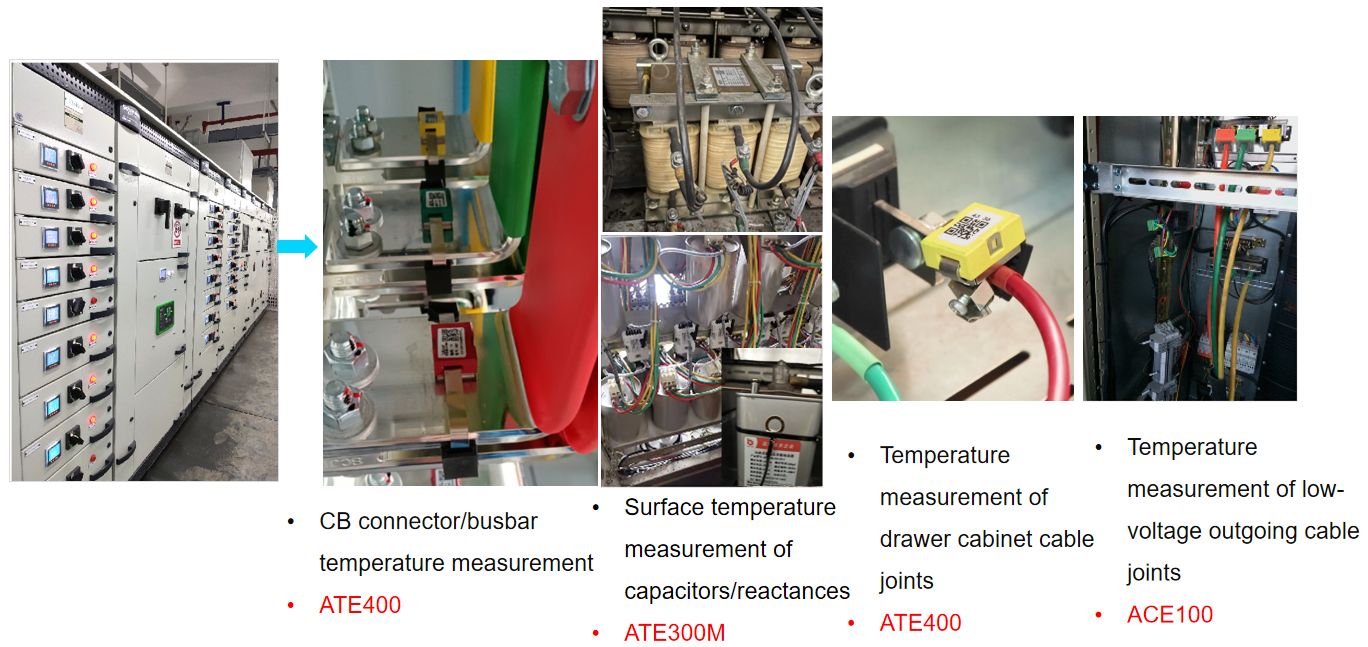

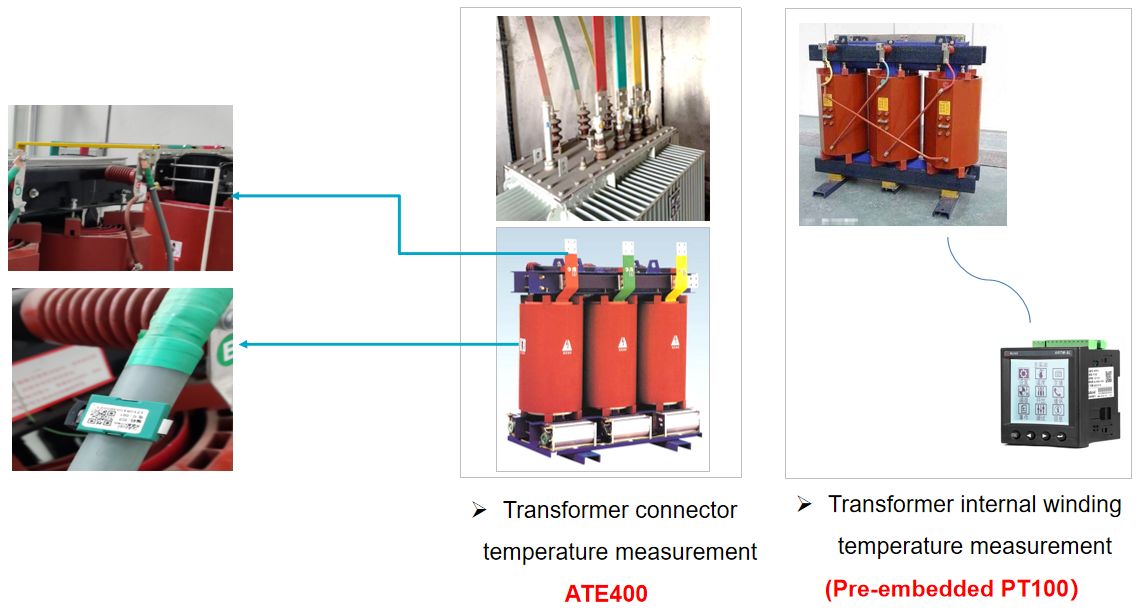

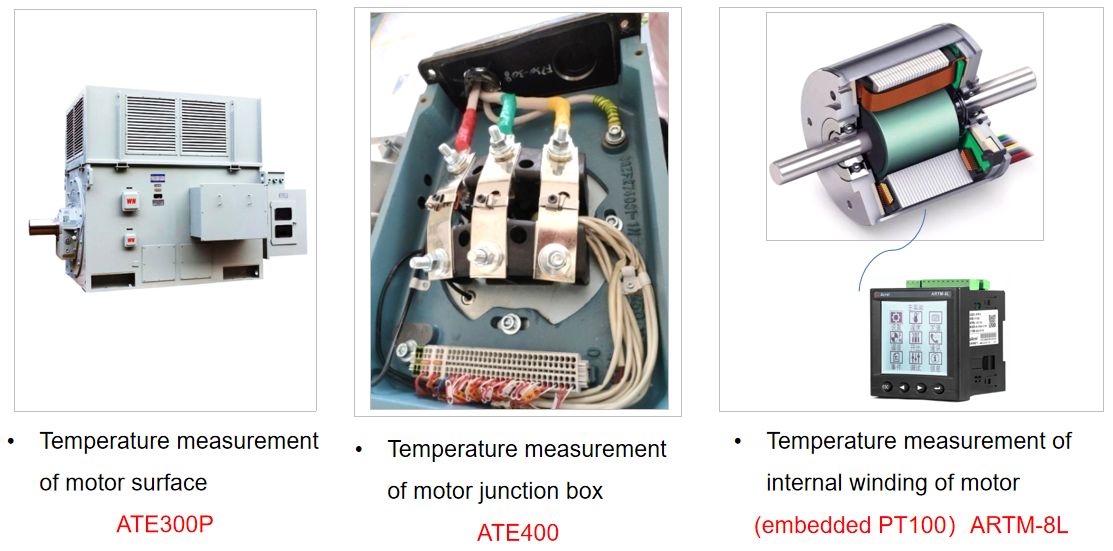

1. Cable connector temperature measurement; 2. Contact temperature measurement; 3. Busbar temperature measurement

Network

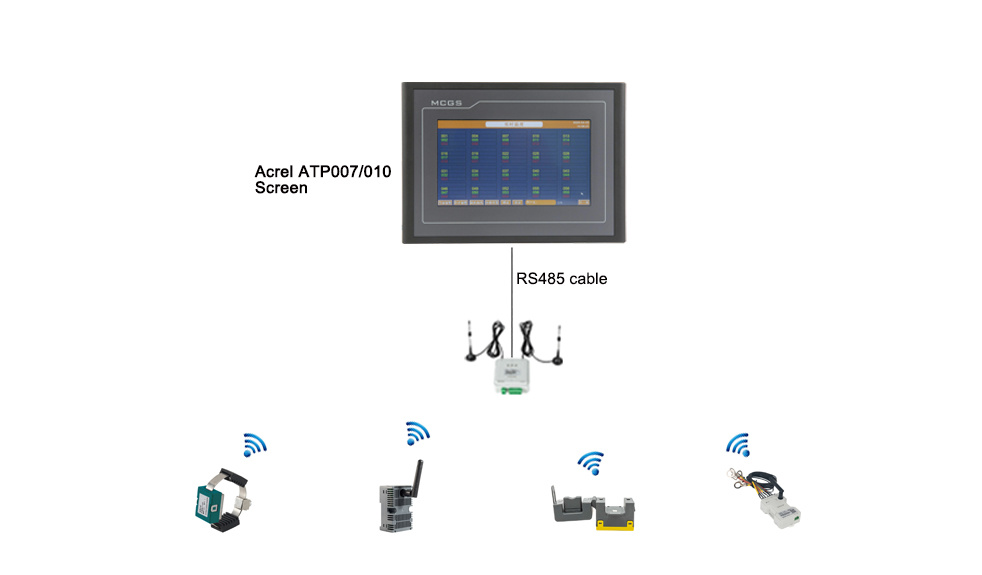

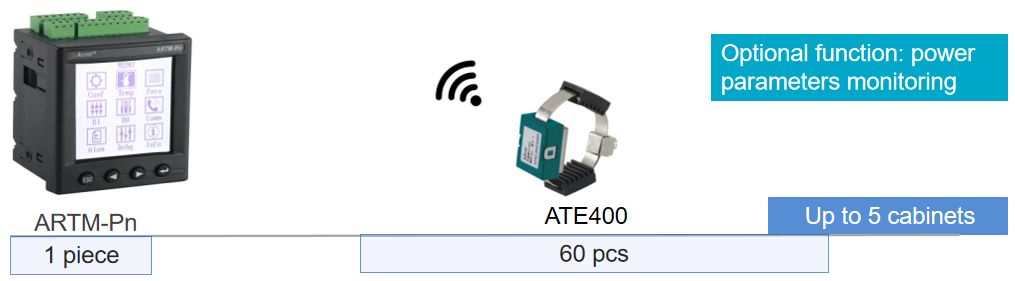

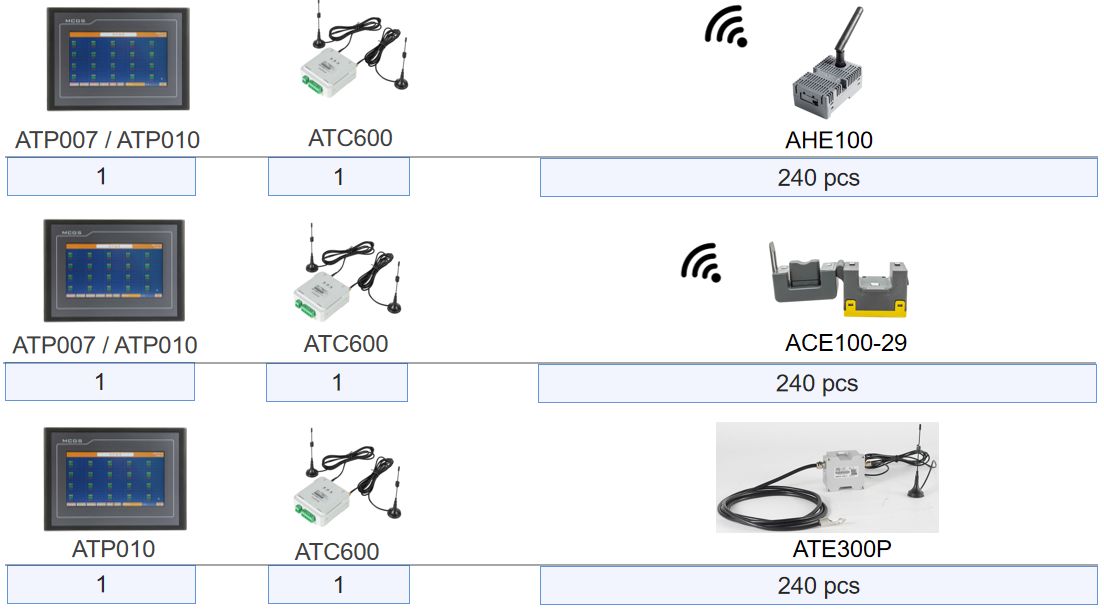

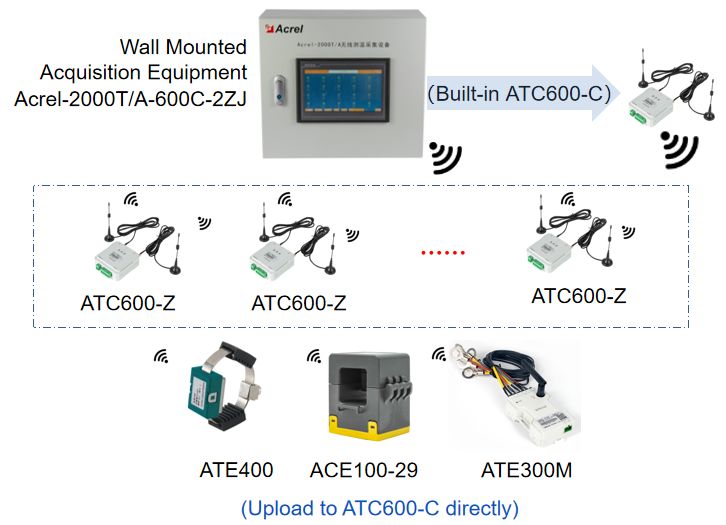

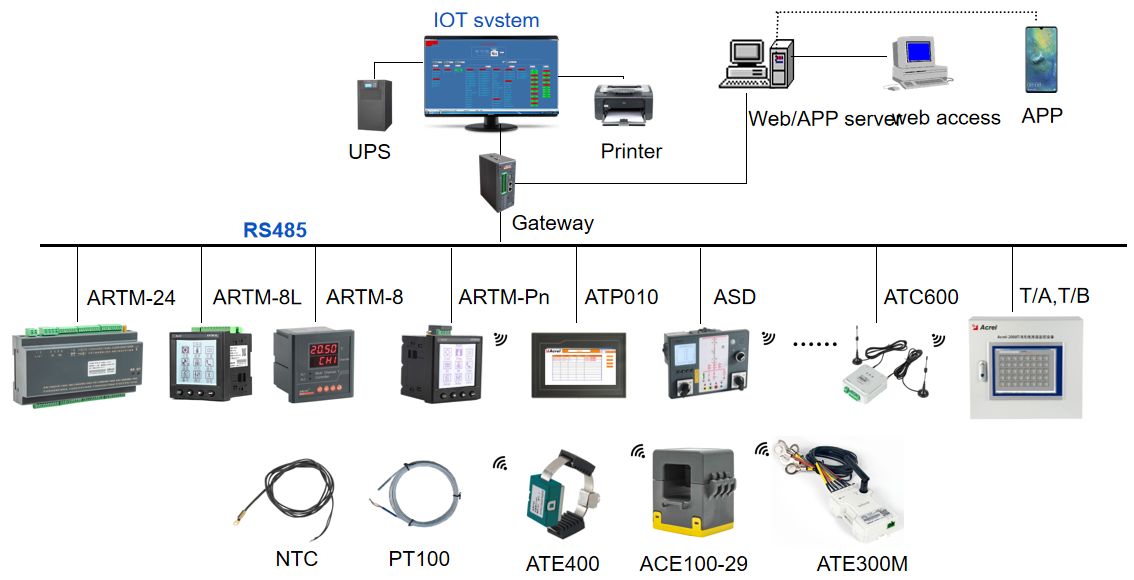

Solution 1: Wireless temperature measurement of electrical contacts in high and low voltage cabinets

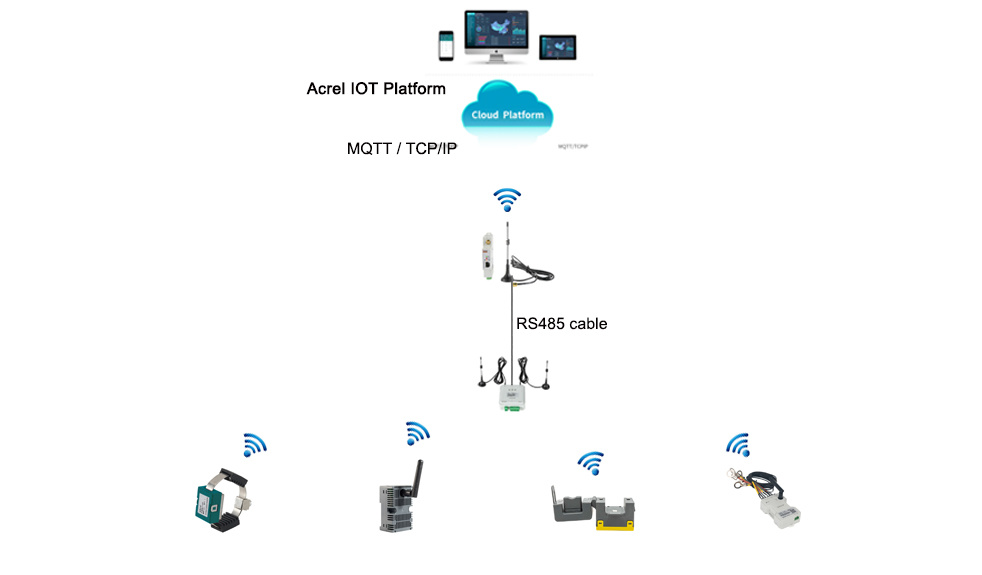

Solution 2: Wireless temperature measurement of electrical contacts in high and low voltage cabinets

Solution 3: On-site wall-mounted centralized display solution

Solution 4: Upload data to IOT Platform

Solution 5: Upload data to IOT Platform

Dimension

Installation

The wireless temperature transceiver ATC600 used with the AHE wireless temperature and humiditysensor can be installed on a rail (DIN35mm)The AHE wireless temperature and humidity sensor adopts the guide rail (DIN35mm) installation

method, and the battery switch needs to be turned on before use.

FAQ

1. Is there any signal interference if more than 40 ACREL units are installed?

Reply: No.

2. How to determine the ID of each sensor which is more than 40 units?

Reply: Every sensor sends the temperature data and its ID to ATC600, then transmits to ATP display screen and IOT platform.

ATP dispaly screen and IOT platform can display the data and position of every sensor. The user can identify them easily.

3. How to make sure the battery can last up to 5 years?

Reply: 5 years is the theoretical value calculated by the average current of the sensor. In actual use, it will be affected by various external factors, for example, the battery life will be greatly shortened under the condition of high temperature for a long time.

4. If the battery runs out in less than 1 year, what is the solution? 如果电池在1年内损坏或者电量耗尽,该怎么处理?

Reply: There are 2 solutions:

1. The batteries in the ATE and AHE sensors can be replaced by new ones.

For ATE100M/200/200P, the Battery model is ER2450T.

You have to welding the two points in the sensor when you change their batteries.

For ATE400, it is strap mounted type, powered through electro-magnetic induction, it has no battery.

For AHE100, its battery model is CR2450, the sensor has battery holder, so the battery is easier to be replaced.

2. We can send new sensors to replace those ones with quality problems.

5. Ensure the receiver's ability to read how many sensor units?

Reply: One ATC600-C can read the data of 240 sensors at most.

One ARTM-Pn can read the data of 60 sensors at most.

6. The current condition is that there are 4 receivers that will be installed, to ensure communication between receivers is not disrupted, for example: receiver 1 must read sensors in building 1, but sensors in building 2 are also read?

Reply: Every transceiver will only display the data of the sensors with the corresponding group number, and even if it receives data from other groups of sensors, it does not matter because each sensor has a unique ID and does not cause confusion.

7. What spare parts are available for the spare sensor unit?

Reply: Transceiver has antenna, connection terminals, ATE400 comes with alloy plate, non-slip pad, locking piece and screws.

8. How to distinguish AHE100 and ATE100M/ATE200 type sensor ID? is it enough with 1 receiver?

Reply: The answer is the same with that of the 2nd question.

Yes, it is enough with 1 receiver.

9. Do i have to send commands to the sensor for getting its temperature readings or it keeps sending temperature data automatically when connected?

Reply: ATE400 sensor monitor the data and uploaded it to ATC600 and IOT every 15 S.

ATE400 monitor tenperature and transmits the data every 15 s, it has nothing to do with temperature fluctuationi.

ATE100/200 and AHE100 measure the temperature every 25S. If the temperature changes more than 4 degrees from the previous temperature, the data will be uploaded to ATC600 and IOT. If the temperature changes less than 4 degrees, the temperature will be uploaded every 5 minutes.

if the temperature fluctuation is less than 4 ℃, is transmits every 5 minutes; if it is large than 4 ℃, it transmits every 25 s.

10. How I should interpret the data when I connect the ATC600 directly to the PC (though RS485)? For example, how I identify each sensor with their respective temp?

Register addresses and sensor codes correspond sequentially, one to one

Other Question? Please contact us and we will get back to you as soon as possible.

Product Description:- PView

- high-performance

- requirements

-

Technical Parameters

-

1. Is there any signal interference if more than 40 ACREL units are installed?

Reply: No.

2. How to determine the ID of each sensor which is more than 40 units?

Reply: Every sensor sends the temperature data and its ID to ATC600, then transmits to ATP display screen and IOT platform.

ATP dispaly screen and IOT platform can display the data and position of every sensor. The user can identify them easily.

3. How to make sure the battery can last up to 5 years?

Reply: 5 years is the theoretical value calculated by the average current of the sensor. In actual use, it will be affected by various external factors, for example, the battery life will be greatly shortened under the condition of high temperature for a long time.

4. If the battery runs out in less than 1 year, what is the solution? 如果电池在1年内损坏或者电量耗尽,该怎么处理?

Reply: There are 2 solutions:

1. The batteries in the ATE and AHE sensors can be replaced by new ones.

For ATE100M/200/200P, the Battery model is ER2450T.

You have to welding the two points in the sensor when you change their batteries.

For ATE400, it is strap mounted type, powered through electro-magnetic induction, it has no battery.

For AHE100, its battery model is CR2450, the sensor has battery holder, so the battery is easier to be replaced.

2. We can send new sensors to replace those ones with quality problems.

5. Ensure the receiver's ability to read how many sensor units?

Reply: One ATC600-C can read the data of 240 sensors at most.

One ARTM-Pn can read the data of 60 sensors at most.

6. The current condition is that there are 4 receivers that will be installed, to ensure communication between receivers is not disrupted, for example: receiver 1 must read sensors in building 1, but sensors in building 2 are also read?

Reply: Every transceiver will only display the data of the sensors with the corresponding group number, and even if it receives data from other groups of sensors, it does not matter because each sensor has a unique ID and does not cause confusion.

7. What spare parts are available for the spare sensor unit?

Reply: Transceiver has antenna, connection terminals, ATE400 comes with alloy plate, non-slip pad, locking piece and screws.

8. How to distinguish AHE100 and ATE100M/ATE200 type sensor ID? is it enough with 1 receiver?

Reply: The answer is the same with that of the 2nd question.

Yes, it is enough with 1 receiver.

9. Do i have to send commands to the sensor for getting its temperature readings or it keeps sending temperature data automatically when connected?

Reply: ATE400 sensor monitor the data and uploaded it to ATC600 and IOT every 15 S.

ATE400 monitor tenperature and transmits the data every 15 s, it has nothing to do with temperature fluctuationi.

ATE100/200 and AHE100 measure the temperature every 25S. If the temperature changes more than 4 degrees from the previous temperature, the data will be uploaded to ATC600 and IOT. If the temperature changes less than 4 degrees, the temperature will be uploaded every 5 minutes.

if the temperature fluctuation is less than 4 ℃, is transmits every 5 minutes; if it is large than 4 ℃, it transmits every 25 s.

10. How I should interpret the data when I connect the ATC600 directly to the PC (though RS485)? For example, how I identify each sensor with their respective temp?

Register addresses and sensor codes correspond sequentially, one to one

Other Question? Please contact us and we will get back to you as soon as possible.

Related Products

Product inquiry

We will contact you within one working day. Please pay attention to your email.

![[object Object] [object Object]](https://omo-oss-image.thefastimg.com/portal-saas/new2023080419495759710/cms/image/138ba837-b50d-4ff3-a73c-2e6a2379c522.jpg)