Acrel ATE400 Wireless Temperature Sensor for Cable/Busbar Temperature Monitoring

Series of products: Products

Series of products: Wireless Temperature and Humidity Monitoring

Series of products: Power Monitoring and Controlling Devices

- Product Description

- Parameters

- Q&A

- Download

-

Overview

ATE series wireless temperature measuring sensor has been developed in compliance with Specification for Wireless Temperature Measuring equipment, NB/T 42086-2016. It is suitable for 3-35kV indoor switchgears, including built-in switchgears, handcart switchgears, fixed switchgears and loop-net switchgears. It is also suitable for 0.4kV low-voltage switchgears such as fixed switchgears and drawer switchgears. The wireless temperature sensors can be installed at any heating point in switchgears, the device utilizes the wireless data transmission technology for real-time transmission of monitored temperature data. In addition, it can be transmitted to display device or remote intelligent monitoring system.

Coding Rule

Dispaly

Mini type passive temperature sensor structure introduction:

1 —— 温度传感器主体The core of wireless temperature sensor ATE400

2 —— 合金底座,与温度探头接触alloy bottom, touched with temperature probe

3 —— 锁扣,用于固定合金片metal hasp, for fixing alloy chip

4 —— 取电合金片,用于感应取电alloy chip, for CT-powered

5 —— 硅胶垫片,用于支撑合金片silicone gasket, used to support the alloy chip

6 —— 合金片安装孔,用于安装合金片alloy chip hole, used to install the alloy chip

Function

● Wireless frequency: 433-470 Mhz

● Communication distance: 150m(470Mhz) 、50m(433Mhz)in open area

● Sampling frequency: 15s

● Transmission frequency: 15s

● Accuracy: ±1℃

● Power source: CT-powered, starting current≥5A, Max current ≤5000A

● Range of temperature: -50℃~125℃

● Application: Joints in high or low voltage switchgears

● Sensor probe: alloy bottom

● Installation: alloy chip fixing

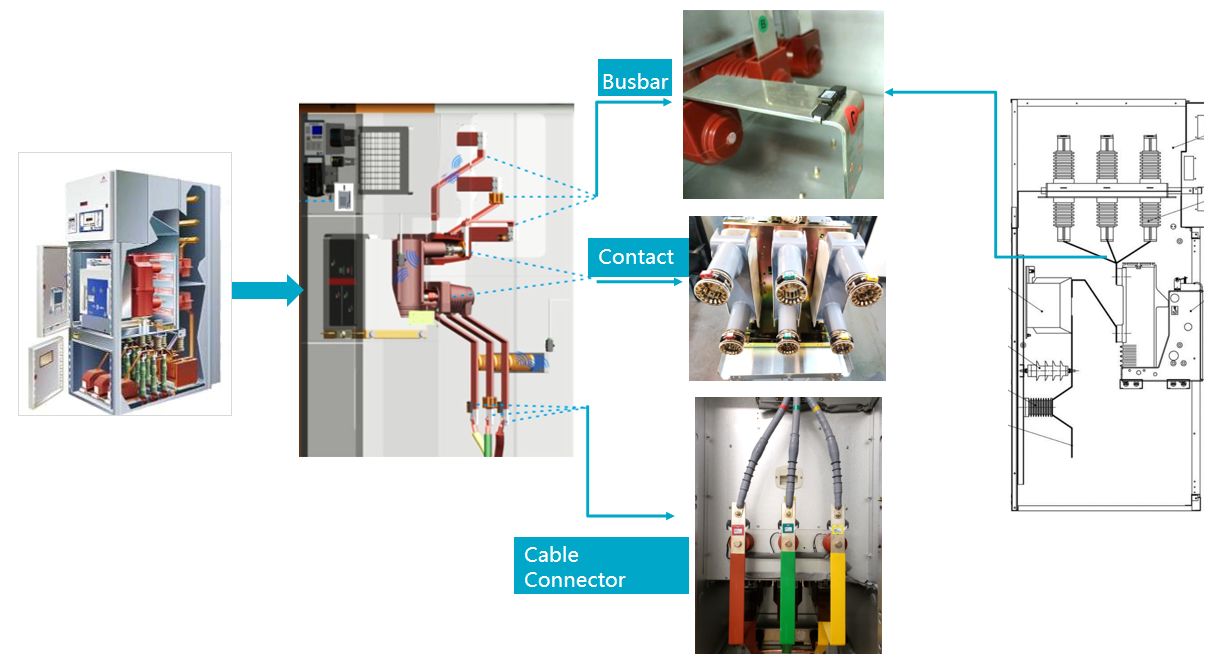

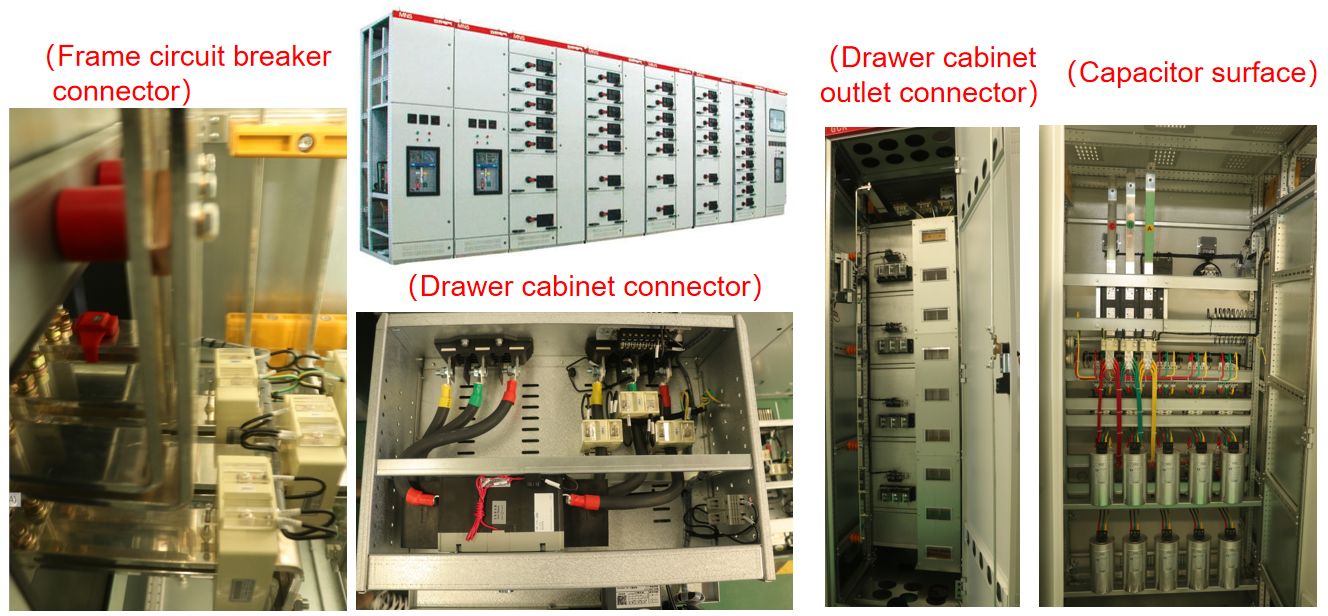

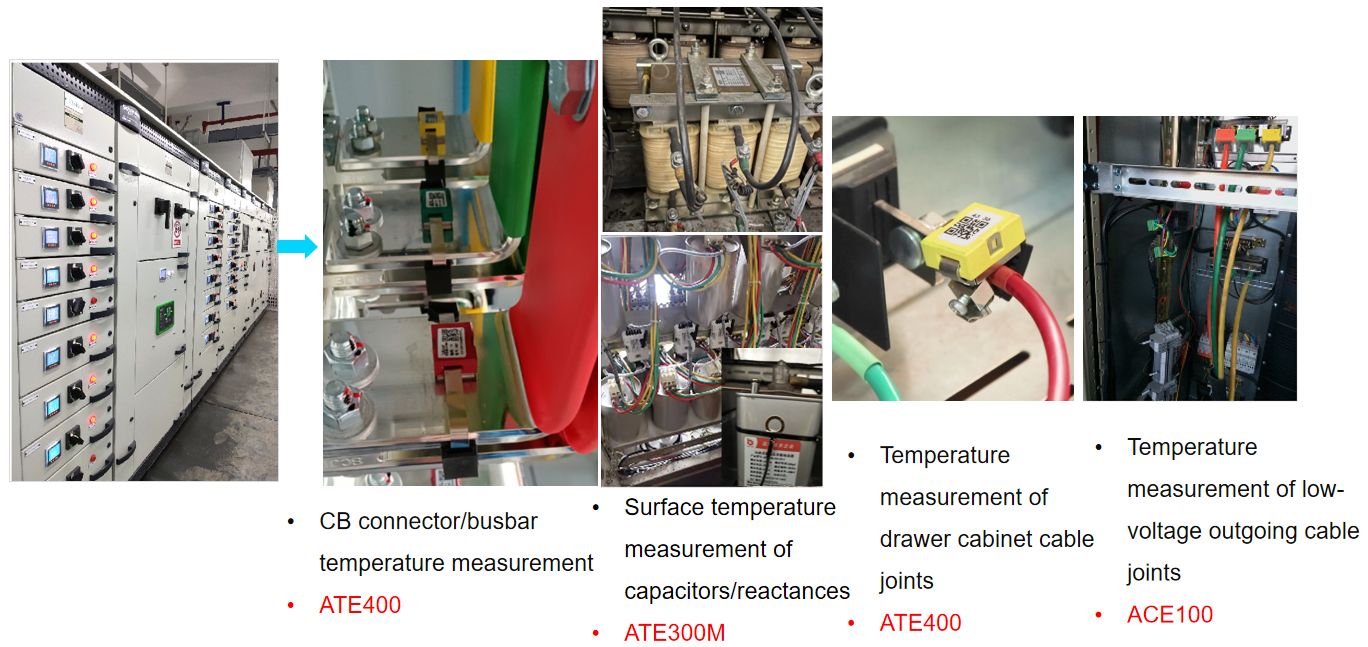

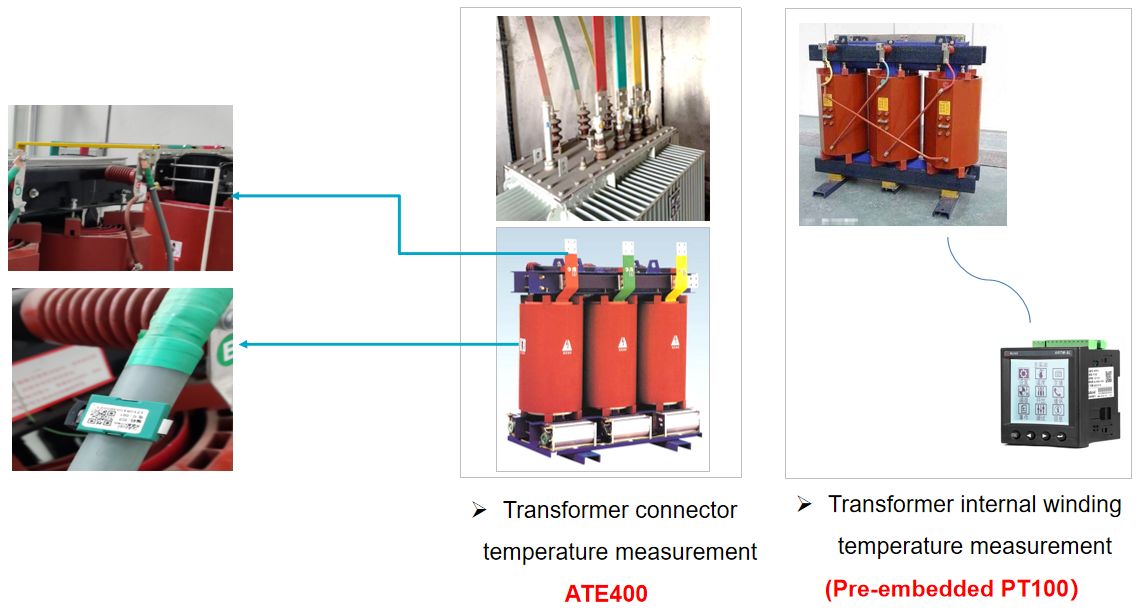

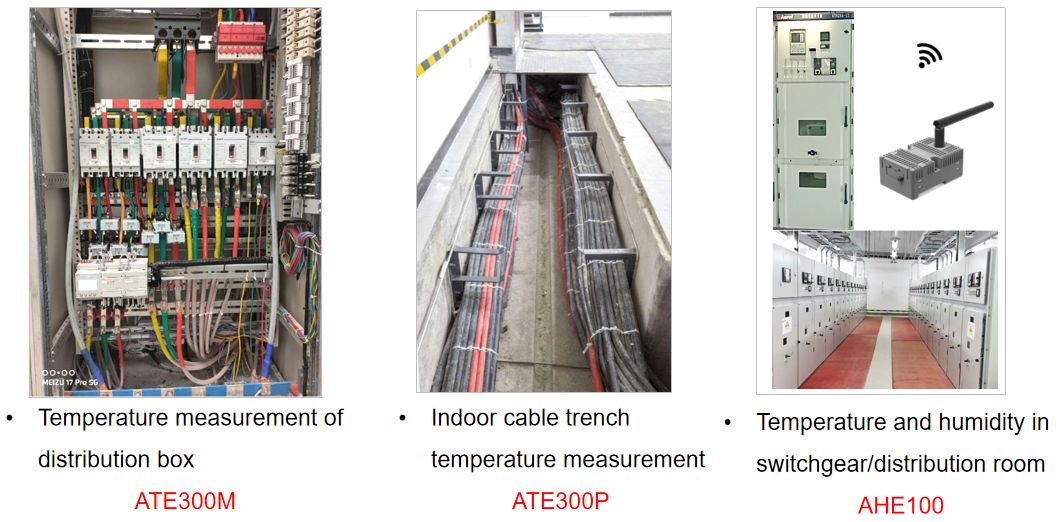

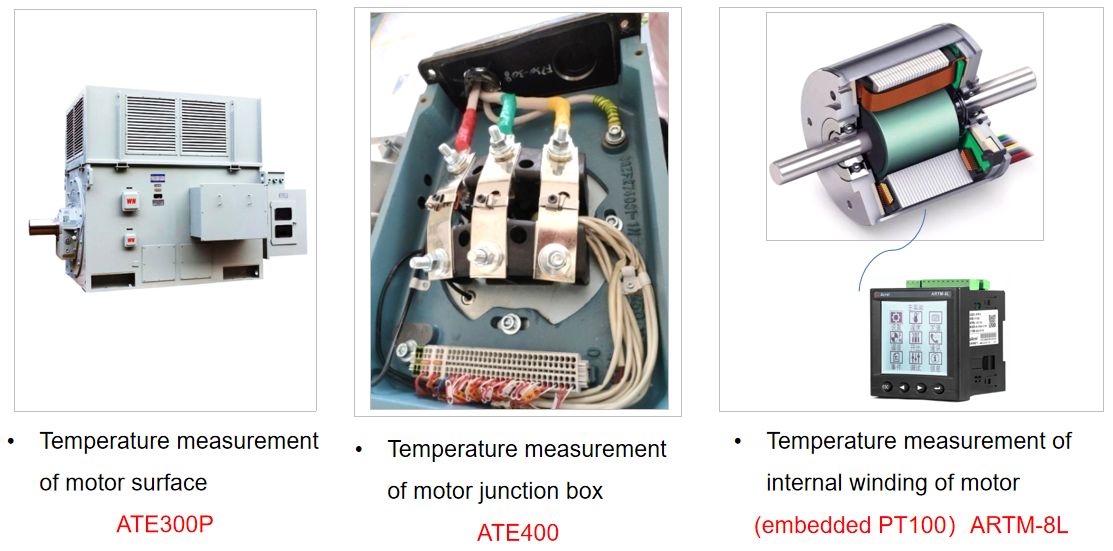

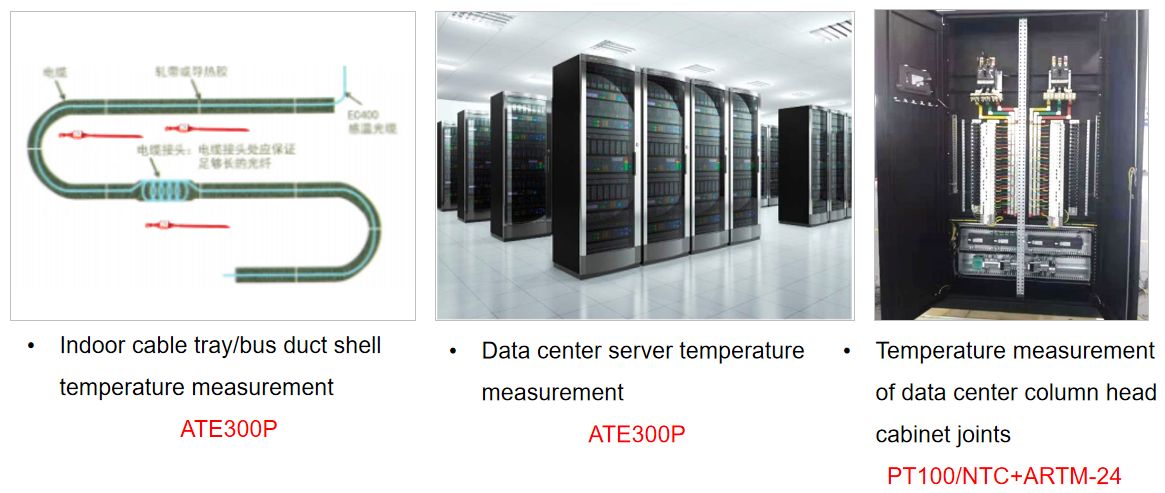

Application

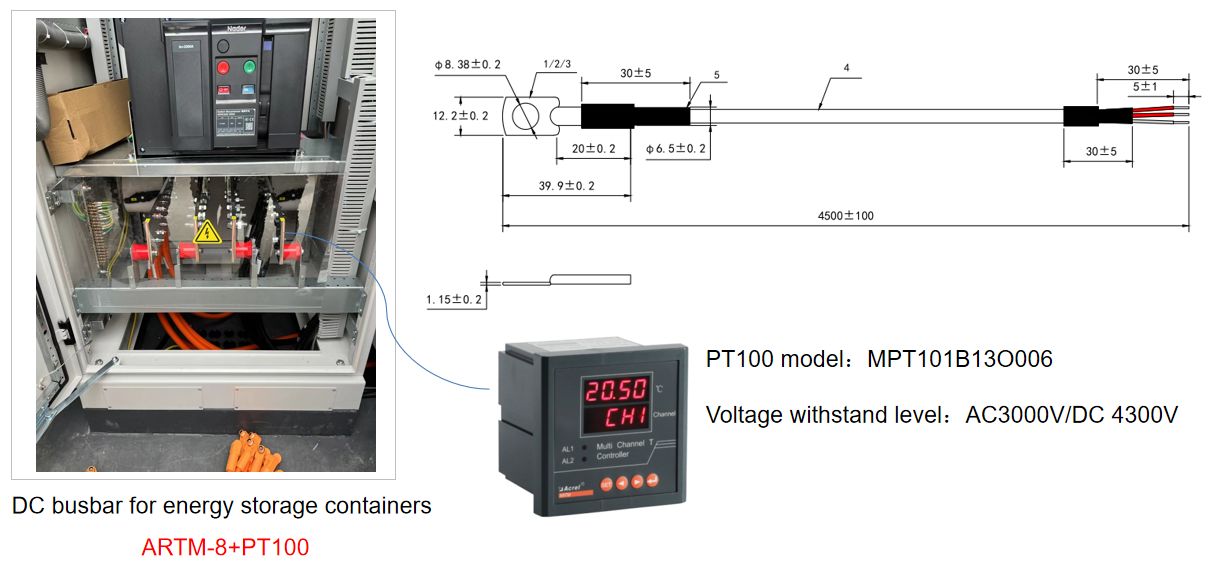

1. Cable connector temperature measurement; 2. Contact temperature measurement; 3. Busbar temperature measurement

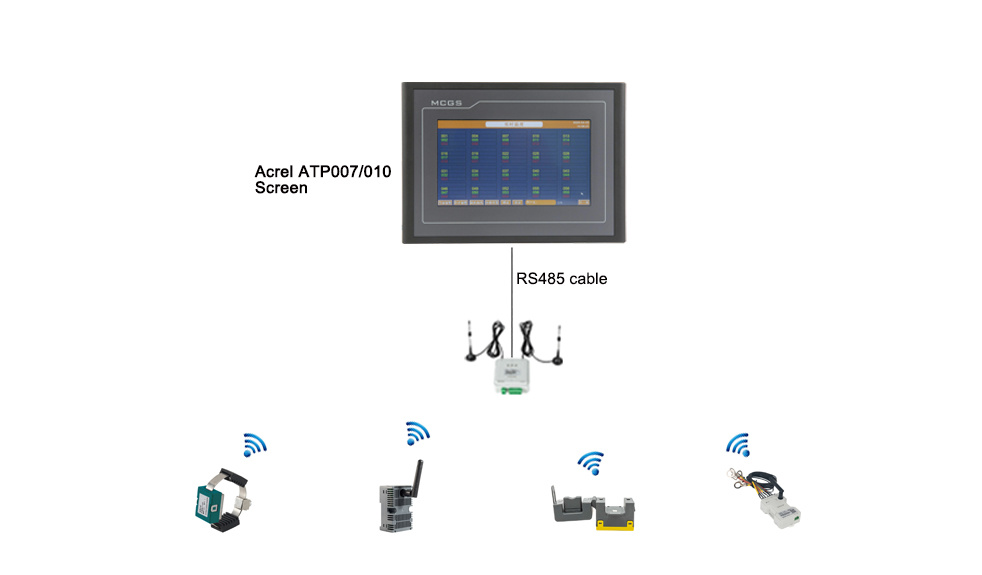

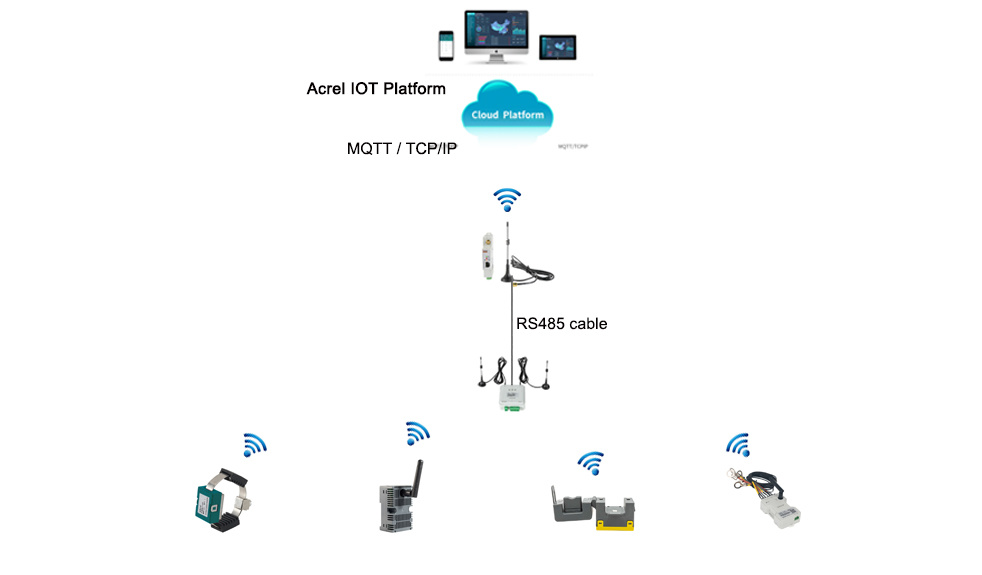

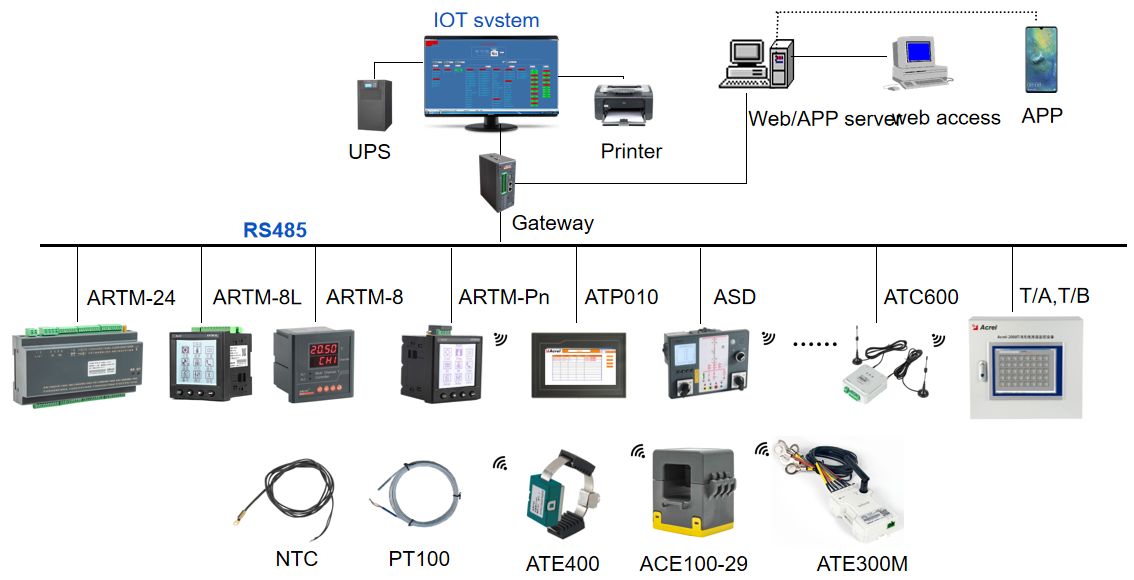

Network

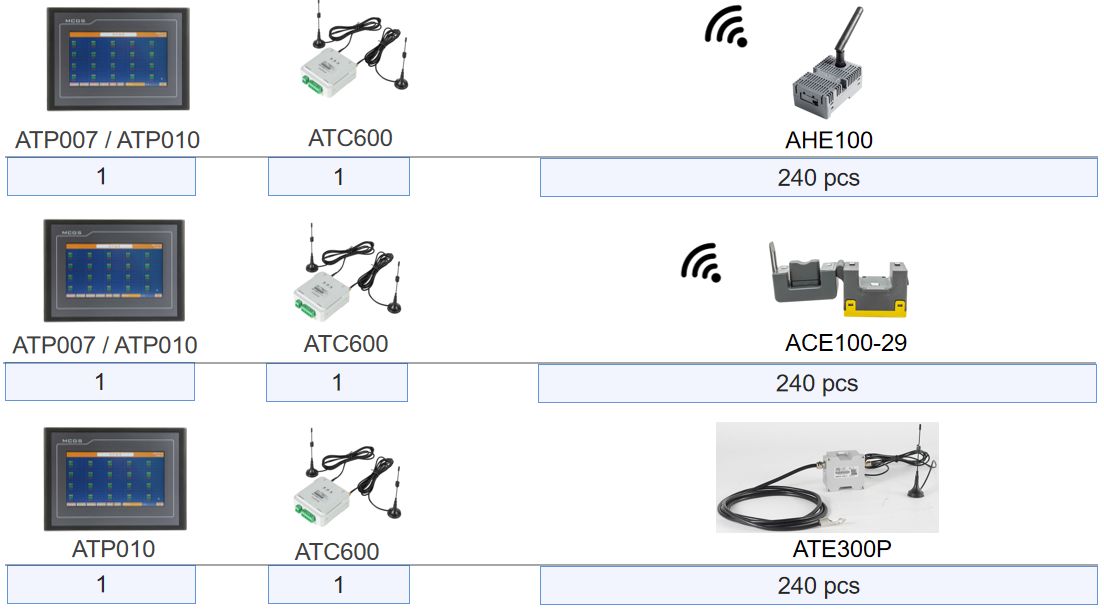

Solution 1: Wireless temperature measurement of electrical contacts in high and low voltage cabinets

Solution 2: Wireless temperature measurement of electrical contacts in high and low voltage cabinets

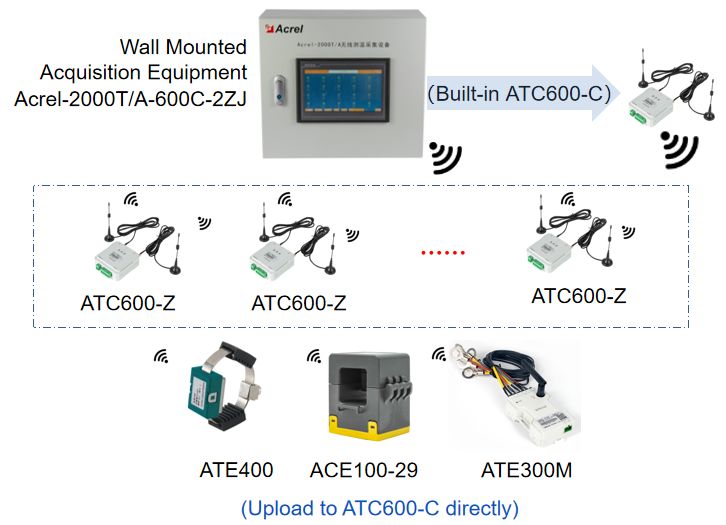

Solution 3: On-site wall-mounted centralized display solution

Solution 4: Upload data to IOT Platform

Solution 5: Upload data to IOT Platform

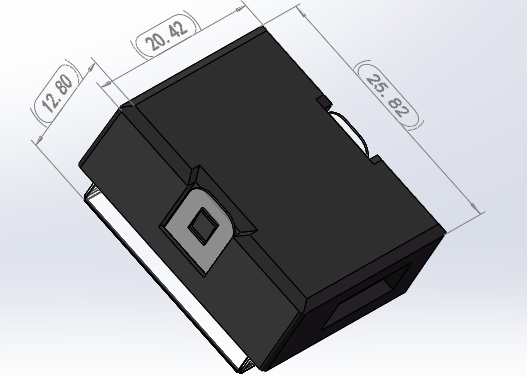

Dimension

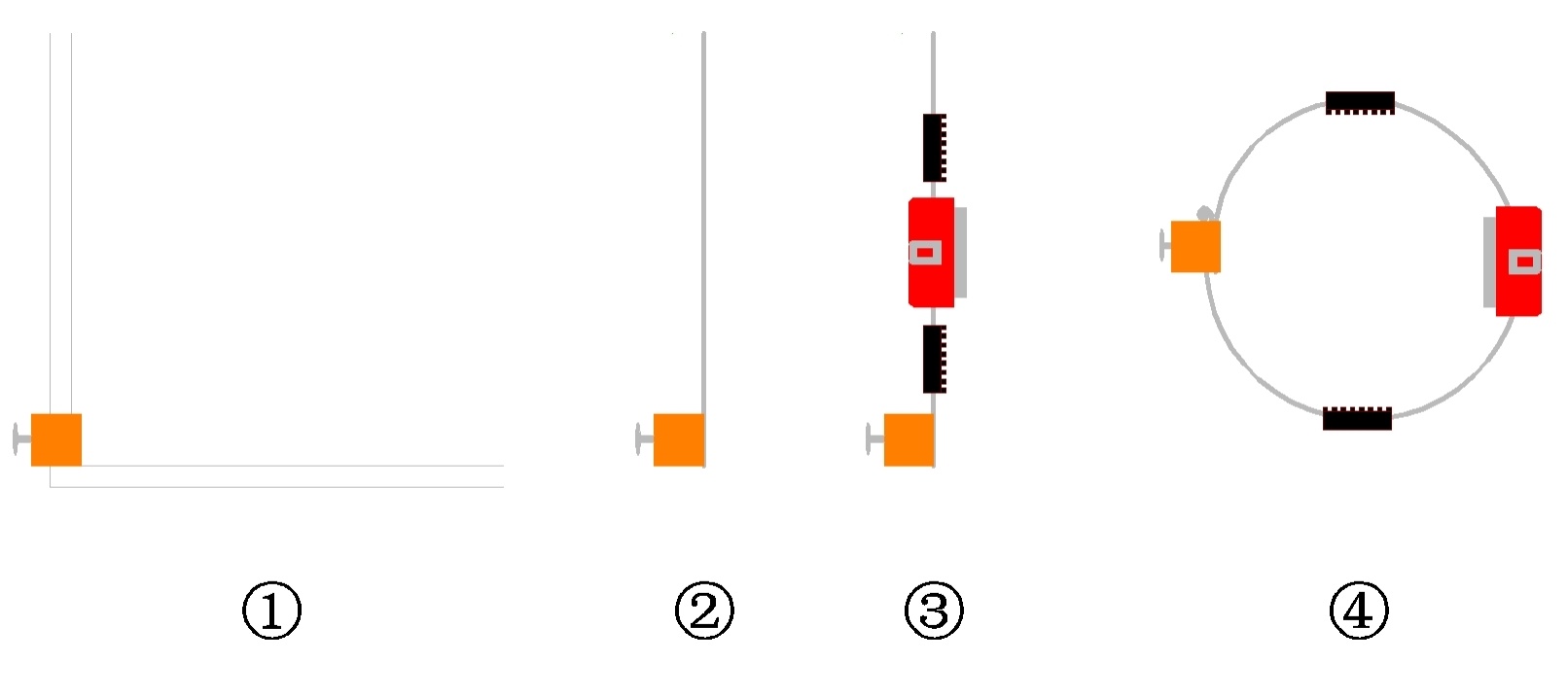

Installation

Firstly, take 2 pieces of alloy chips through the mounting hole of metal hasp, meanwhile fold the alloy chips and fix the metal hasp in the middle of alloy chips.

Secondly, take the folded alloy chips through one silicone gasket, the core of ATE400 and another silicone gasket in turn.

Thirdly, circle the whole alloy chips around the mounting position and tension the alloy chips, then tighten the screw on the metal hasp.

Finally, subtract the excess alloy chips. The complete installation process is shown in Figures 1 to 4.

Note: ATE400 can be installed with fixed contact, copper plate and cable head; If it is necessary to install moving contacts, it is necessary to consider the height of plum blossom head and sleeve is sufficient.

FAQ

1. Is there any signal interference if more than 40 ACREL units are installed?

Reply: No.

2. How to determine the ID of each sensor which is more than 40 units?

Reply: Every sensor sends the temperature data and its ID to ATC600, then transmits to ATP display screen and IOT platform.

ATP dispaly screen and IOT platform can display the data and position of every sensor. The user can identify them easily.

3. How to make sure the battery can last up to 5 years?

Reply: 5 years is the theoretical value calculated by the average current of the sensor. In actual use, it will be affected by various external factors, for example, the battery life will be greatly shortened under the condition of high temperature for a long time.

4. If the battery runs out in less than 1 year, what is the solution? 如果电池在1年内损坏或者电量耗尽,该怎么处理?

Reply: There are 2 solutions:

1. The batteries in the ATE and AHE sensors can be replaced by new ones.

For ATE100M/200/200P, the Battery model is ER2450T.

You have to welding the two points in the sensor when you change their batteries.

For ATE400, it is strap mounted type, powered through electro-magnetic induction, it has no battery.

For AHE100, its battery model is CR2450, the sensor has battery holder, so the battery is easier to be replaced.

2. We can send new sensors to replace those ones with quality problems.

5. Ensure the receiver's ability to read how many sensor units?

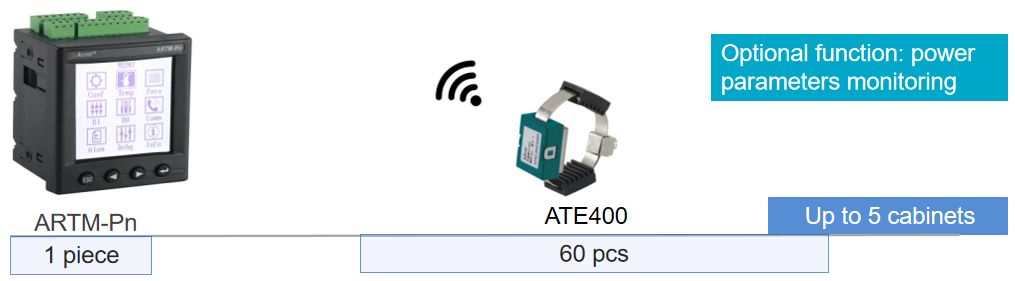

Reply: One ATC600-C can read the data of 240 sensors at most.

One ARTM-Pn can read the data of 60 sensors at most.

6. The current condition is that there are 4 receivers that will be installed, to ensure communication between receivers is not disrupted, for example: receiver 1 must read sensors in building 1, but sensors in building 2 are also read?

Reply: Every transceiver will only display the data of the sensors with the corresponding group number, and even if it receives data from other groups of sensors, it does not matter because each sensor has a unique ID and does not cause confusion.

7. What spare parts are available for the spare sensor unit?

Reply: Transceiver has antenna, connection terminals, ATE400 comes with alloy plate, non-slip pad, locking piece and screws.

8. How to distinguish AHE100 and ATE100M/ATE200 type sensor ID? is it enough with 1 receiver?

Reply: The answer is the same with that of the 2nd question.

Yes, it is enough with 1 receiver.

9. Do i have to send commands to the sensor for getting its temperature readings or it keeps sending temperature data automatically when connected?

Reply: ATE400 sensor monitor the data and uploaded it to ATC600 and IOT every 15 S.

ATE400 monitor tenperature and transmits the data every 15 s, it has nothing to do with temperature fluctuationi.

ATE100/200 and AHE100 measure the temperature every 25S. If the temperature changes more than 4 degrees from the previous temperature, the data will be uploaded to ATC600 and IOT. If the temperature changes less than 4 degrees, the temperature will be uploaded every 5 minutes.

if the temperature fluctuation is less than 4 ℃, is transmits every 5 minutes; if it is large than 4 ℃, it transmits every 25 s.

10. How I should interpret the data when I connect the ATC600 directly to the PC (though RS485)? For example, how I identify each sensor with their respective temp?

Register addresses and sensor codes correspond sequentially, one to one

Other Question? Please contact us and we will get back to you as soon as possible.

Product Description:- PView

- high-performance

- requirements

-

Technical Features

项目

Items

指标

Features

环境要求

Environment

工作温度

Temperature

-40℃~85℃

相对湿度

Humidity

≤95%

大气压力

86kPa~106kPa

ATE100M/100/200有源无线温度传感器

ATE100M/100/200 Active wireless temperature sensor

无线频率

Wireless frequency

470MHz、433Mhz

通讯距离

Communication distance

空旷150m(470Mhz)、空旷50m(433Mhz)

150m(470Mhz) 、50m(433Mhz)in open area

采样频率

Sampling frequency

25s

发射频率

Transmitting frequency

25s-5min

工作电源

Power source

电池

Battery

安装方式

Installation

磁吸式/螺栓式/表带式

Magnetic / bolted /Belt

测温范围

Range of temperature

-50℃~+125℃

精度

Precision

±1℃

应用范围

Application

高低压柜内电气接头

Joints in high or low voltage switchgears

电池寿命

Battery life

≥5年(25℃)

≥5 years(25℃)

400无源无线温度传感器

400 Passive wireless temperature sensor

无线频率

Wireless frequency

470MHz、433Mhz

通讯距离

Communication distance

空旷150m(470Mhz)、空旷50m(433Mhz)

150m(470Mhz) 、50m(433Mhz)in open area

采样频率

Sampling frequency

15s

发射频率

Transmission frequency

15s

工作电源

Power source

CT感应取电,启动电流≥5A

CT-powered, starting current≥5A

最大工作电流(Max current)≤5000A

安装方式

Installation

合金片固定

alloy chip fixing

传感器探头

Sensor probe

合金底座

alloy bottom

测温范围

Range of temperature

-50℃~125℃

精度

Precision

±1℃

应用范围

Application

高低压柜内电气接头

Joints in high or low voltage switchgears

ATE100P/200P户外无线温度传感器

ATE100P/200P Outdoor wireless temperature sensor

无线频率

Wireless frequency

470MHz、433Mhz

通讯距离

Communication distance

空旷150m(470Mhz)、空旷50m(433Mhz)

150m(470Mhz) 、50m(433Mhz)in open area

采样频率

Sampling frequency

25s

发射频率

Transmitting frequency

25s-5min

工作电源

Power source

电池

Battery

安装方式

Installation

螺栓式/表带式

bolted /Belt

测温范围

Range of temperature

-50℃~+150℃

精度

Precision

±0.5℃

应用范围

Application

电气接头

Voltage switchgears

电池寿命

Battery life

≥5年(25℃)

≥5 years(25℃)

防护等级

Protection level

IP68

ATE300M多回路式温度传感器

ATE300M multi

Loop temperature sensor

无线频率

Wireless frequency

433-510MHz

通讯距离

Communication distance

空旷1000m

1000m in open area

采集频率

Sampling frequency

1-240s

工作电源

Power source

AC/DC 85~265V

安装方式

Installation

导轨式/扎带式

测温范围

Range of temperature

-40℃~+140℃

精度

Precision

±1℃

应用范围

Application

低压抽屉柜内电气接头

Joints in low voltage switchgears

-

1. Is there any signal interference if more than 40 ACREL units are installed?

Reply: No.

2. How to determine the ID of each sensor which is more than 40 units?

Reply: Every sensor sends the temperature data and its ID to ATC600, then transmits to ATP display screen and IOT platform.

ATP dispaly screen and IOT platform can display the data and position of every sensor. The user can identify them easily.

3. How to make sure the battery can last up to 5 years?

Reply: 5 years is the theoretical value calculated by the average current of the sensor. In actual use, it will be affected by various external factors, for example, the battery life will be greatly shortened under the condition of high temperature for a long time.

4. If the battery runs out in less than 1 year, what is the solution? 如果电池在1年内损坏或者电量耗尽,该怎么处理?

Reply: There are 2 solutions:

1. The batteries in the ATE and AHE sensors can be replaced by new ones.

For ATE100M/200/200P, the Battery model is ER2450T.

You have to welding the two points in the sensor when you change their batteries.

For ATE400, it is strap mounted type, powered through electro-magnetic induction, it has no battery.

For AHE100, its battery model is CR2450, the sensor has battery holder, so the battery is easier to be replaced.

2. We can send new sensors to replace those ones with quality problems.

5. Ensure the receiver's ability to read how many sensor units?

Reply: One ATC600-C can read the data of 240 sensors at most.

One ARTM-Pn can read the data of 60 sensors at most.

6. The current condition is that there are 4 receivers that will be installed, to ensure communication between receivers is not disrupted, for example: receiver 1 must read sensors in building 1, but sensors in building 2 are also read?

Reply: Every transceiver will only display the data of the sensors with the corresponding group number, and even if it receives data from other groups of sensors, it does not matter because each sensor has a unique ID and does not cause confusion.

7. What spare parts are available for the spare sensor unit?

Reply: Transceiver has antenna, connection terminals, ATE400 comes with alloy plate, non-slip pad, locking piece and screws.

8. How to distinguish AHE100 and ATE100M/ATE200 type sensor ID? is it enough with 1 receiver?

Reply: The answer is the same with that of the 2nd question.

Yes, it is enough with 1 receiver.

9. Do i have to send commands to the sensor for getting its temperature readings or it keeps sending temperature data automatically when connected?

Reply: ATE400 sensor monitor the data and uploaded it to ATC600 and IOT every 15 S.

ATE400 monitor tenperature and transmits the data every 15 s, it has nothing to do with temperature fluctuationi.

ATE100/200 and AHE100 measure the temperature every 25S. If the temperature changes more than 4 degrees from the previous temperature, the data will be uploaded to ATC600 and IOT. If the temperature changes less than 4 degrees, the temperature will be uploaded every 5 minutes.

if the temperature fluctuation is less than 4 ℃, is transmits every 5 minutes; if it is large than 4 ℃, it transmits every 25 s.

10. How I should interpret the data when I connect the ATC600 directly to the PC (though RS485)? For example, how I identify each sensor with their respective temp?

Register addresses and sensor codes correspond sequentially, one to one

Other Question? Please contact us and we will get back to you as soon as possible.

Related Products

Product inquiry

We will contact you within one working day. Please pay attention to your email.

![[object Object] [object Object]](https://omo-oss-image.thefastimg.com/portal-saas/new2023080419495759710/cms/image/138ba837-b50d-4ff3-a73c-2e6a2379c522.jpg)